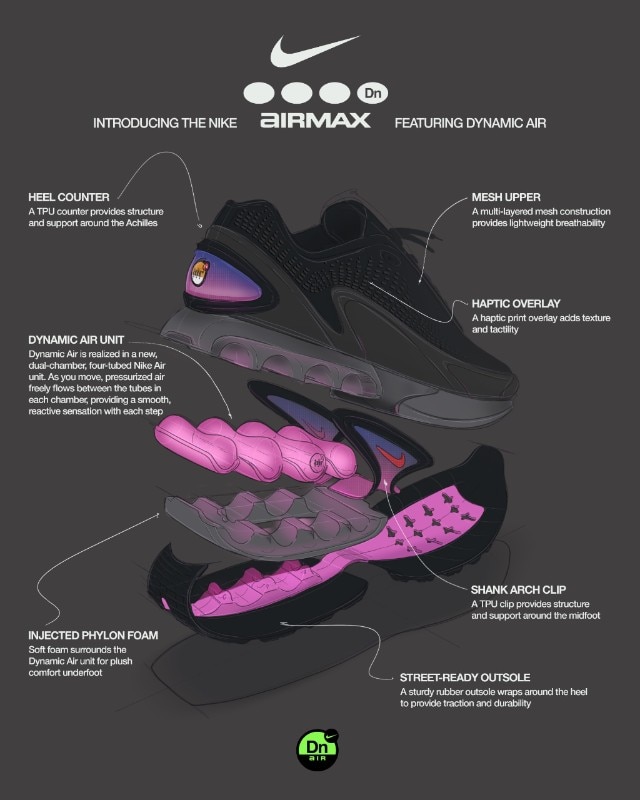

“Always take a step forward,” says Kathy Gomez, VP of Footwear Innovation at Nike, as she introduces the new Air Max Dn to Domus. Bold lines, various colorways, the black with purple/fuchsia gradient detailing stands out the most. The logo inscribed in a cloud climbs up from the sole to the upper, with a prominent thick sole and four soft cylinders facing the sides of the heel, giving it a fun, cheeky, and attention-grabbing appearance. It’s hard to miss the new Air Max Dn, an offspring of the series that has defined the present and future of sneakers on streets worldwide for over three decades.

The first in the series, the Air Max 1, drew inspiration from the Pompidou; it was so distinct and disruptive to the sneaker landscape of its time that its creator, Tinker Hatfield, a legendary shoe designer, recalls being told before its launch that he had “gone too far” and they wanted to fire him. Drawing on the Parisian architecture of Rogers and Piano, as well as Franchini, this ‘87 sneaker reintroduced the concept of exposing the functional elements, particularly the Air pads on the sole, through a small “window”. Like the Pompidou, it has since become an icon.

The Ever-Evolving Legacy of Air Max

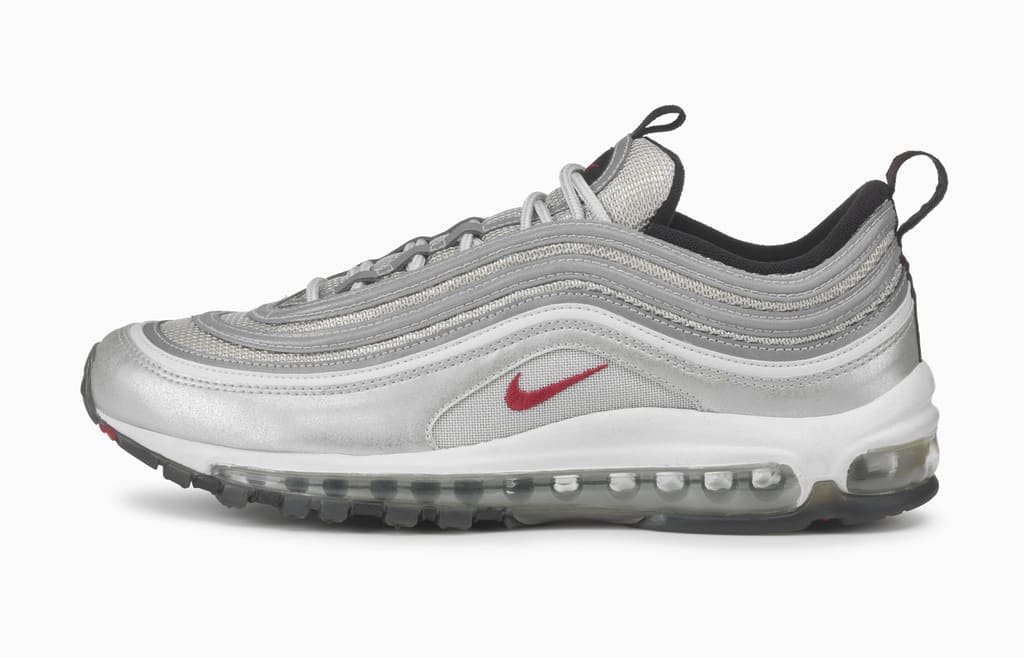

The small “window” on the sole of the first model gradually evolved over the years, defining shoes that have become classics, cult items, and mythology: the 95, the first to feature Air cushions even in the forefoot area, the 97 – the “silver” – the Tn, and so on, not to mention the endless variations with different colorways, often in limited editions – the “infrared”, the “safari”, the “elephant”. In the last decade, the VaporMax (2017) pushed the idea of “showing” to the limit by introducing soles with visible padding, and the Scorpion expanded the concept even further.

“How do you take something so iconic and keep it relevant?” The question Gomez asks as she shows and almost caresses the new Air Maxes in a sunlit room overlooking the Oregon woods at Nike’s Beaverton campus is not just marketing rhetoric. It’s the unveiling of a design philosophy. Nike’s answer with the Dn’s was a technological paradigm shift. That is, to “take compressed air from a static idea to a dynamic idea. Putting air front and center. And create a new beginning for Air Max.”

Exploring the Nike Air Manufacturing Center

Nike has opened the doors of Air Manufacturing Innovation, one of two facilities that produce Air units, to Domus. It’s located a short distance from campus, about a ten-minute walk, as distances are measured in Beaverton. This proximity isn’t just convenient; it’s essential for the development of Nike shoes, with Air being the beating heart that reaches its pinnacle in the Air Maxes, both in functionality and representation.

It also has a fresh look, which means there’s something different: that’s your Max, but it’s different.

Kathy Gomez

Anna Schonberg, VP of manufacturing and engineering, serves as Domus’ Virgil at the factory’s threshold, a place rarely open to visitors. “This is where the magic happens.” Sheets of TPU, a material blending plastic and rubber properties, are transformed into nitrogen-filled capsules that will propel the steps and runs of people worldwide, from Olympic athletes to commuters wearing the new Air Max Dn’s. With about 500 patents in Nike Air technology, the company churns out roughly 100 million pairs annually. The Air Manufacturing Innovation Center employs about 800 people, including 250 engineers. “Creativity, ingenuity, and magic,” says Schonberg, “are what set us apart. The factory never stops, not even during Covid.”

Air made its debut in 1978 on the Tailwind running shoe, the brainchild of Frank Rudy, a NASA engineer. Airbags in the soles not only cushioned but also conserved energy, giving athletes more momentum during rebounds. “Air is a powerful technology because it works, and that’s what matters,” Gomez explains, listing its benefits: it cushions trauma “like nothing else,” is resilient, and “always returns to its original state.”

It’s hard to imagine Nike today without Air, a solution that has become almost ubiquitous in Swoosh shoes. And it continues to innovate because “if you don’t innovate, the platform just becomes a reference and it’s no longer relevant,” Gomez tells Domus. Today, Air can do things that were once impossible. “The engineering tools allow us to achieve precision that was unthinkable 10 years ago.” And so, here is the new Dynamic Air module of the Air Max Dn.

Dynamic Air: A New Era of Nike Air Begins

This unprecedented air unit has two chambers with different pressures, the one at the heel with higher pressure, each consisting of two connected tubes. As you walk, air circulates freely from one to the other, creating an “interactive” fluid feel with every step. And it’s not all about functionality: “It also has a fresh look,” explains Gomez, “which means there’s something different: that’s your Max, but it’s different,” Kathy Gomez sums up in a phrase that’s already a slogan.

All images Courtesy Nike